- Home

- About us

- Products

- Dealer Enquiry

- Blog

- Contact Us

- Home

- About us

- Products

- Dealer Enquiry

- Contact Us

- 044 -2486 1994

- +91 99623 98222

- sales@nantech.in

- REQUEST A QUOTE

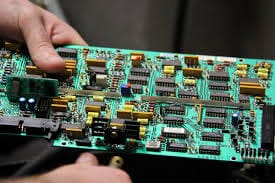

Before UPS dealers in Chennai get their shipment to sell UPS systems to the customer, they are manufactured and tested. Experts at Nantech believe that there are too many tests performed on any uninterrupted power supply to list in a single article. Therefore, we tackle only six types of testing that are executed after the battery is assembled in a manufacturing shop.

One of the tests done at Nantech is the Power Frequency Voltage Withstand Test. In this examination, a fifty or sixty Hertz voltage is applied to parts of the battery for sixty seconds. These specifications may be altered if the supplier approved test differs. Before the testing is conducted, the following components are removed:

If the circuit has an earthing, then that is removed too. No defects are to found in this test.

The second test that is carried out by Nantech to ensure that our customers get the very best of products is the Operation Test. In this examination, a power source device or test battery is given a simulated load for:

Nantech meets the acceptance criteria as quoted by the manufacturer in the approved test procedure, for every single test. Only a UPS that fulfils the operation standards is given the A-Okay by us.

Also Read: A few guidelines for the safe and efficient operation of your UPS!

The next on the barrage of tests we do at Nantech is called the A-C Output Characteristic Test. In this examination, the test results should meet the performance of the battery as given by UPS manufacturer or any other approved data sheet. The A-C test is carried by providing a combination of simulated battery and simulated load. To make certain that the batteries supplied by Nantech are near perfect, we conduct the next test.

The Voltage Adjustment Range Test is started by keeping the a-c input voltage and a-c output current at a set value. Then the a-c output voltage range is measured while keeping the voltage regulator within the upper or lower limit. The variable range, thus measured, should not fall below the specified number given by the approved procedure.

The last two tests conducted by Nantech to offer the best in class batteries to dealers in Chennai are the Output voltage accuracy testing and transient output voltage characteristic testing. The first testing measures the variation in the a-c output voltage by setting the input voltage at the rated value. In each case, the output current should be 100%, 50% or 0% of the rated current. The accuracy should fall within the limit specified by the testing procedure approved by the manufacturer. The last testing was created to test that the transient fluctuation of the output voltage always remains within the limit set by approved methods.

Besides the tests explained above, there are three more tests that need to be given a special mention. The experts at Nantech perform the Insulation Resistance Test once before the voltage withstand test and once after it. In both cases, the value of resistance should be 3 M Ohm or above it. The amount can differ if so specified in the approved testing method. A 500 Volt insulation resistance tester is used in this procedure.

Another test that is crucial to the performance of UPS batteries is the temperature rise test. It is conducted using a thermometer. The temperature should not go above a set limit when the battery is used at the rated a-c input voltage, frequency, and output. The temperature should remain within the applicable standards. Similarly, the overload capability test is crucial. A UPS battery should be able to bear an overload condition. The endurance should be in keeping to the level approved by manufacturer’s testing procedure. This is to make sure that when the battery is actually used, it is entirely safe to do so.

All the UPS manufacturers must conform to all the mandatory tests to ensure product quality and reliability.